Our school,Szeged Vocational Center Miksa Deri Technical School is located in Szeged, the regional centre of the the southern region of Hungary near the borders to Serbia and Romania, about 180 kms from the capital of the country, Budapest. Our school was founded in 1894, it is one of the oldest educational institutions of the region. In 2020 we started the 126th academic year. Although the school was renamed several times and the vocational training system of Hungary is undergoing a structural change, the basic principles remained the same: to prepare students for further studies in the technical field, to provide students basic and specialised technical knowledge. We offer training programmes in three sectors of technical field: mechanical and electrical engineering, ICT. Machine and CNC cutting, industrial IT technician, mechatronics technician, automation technician, manufacturing engineering technician and electronics technician courses are available now. The school has about 650 students and 85 teachers.

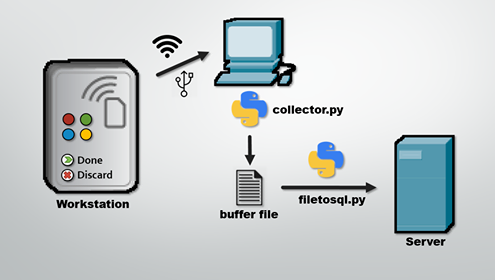

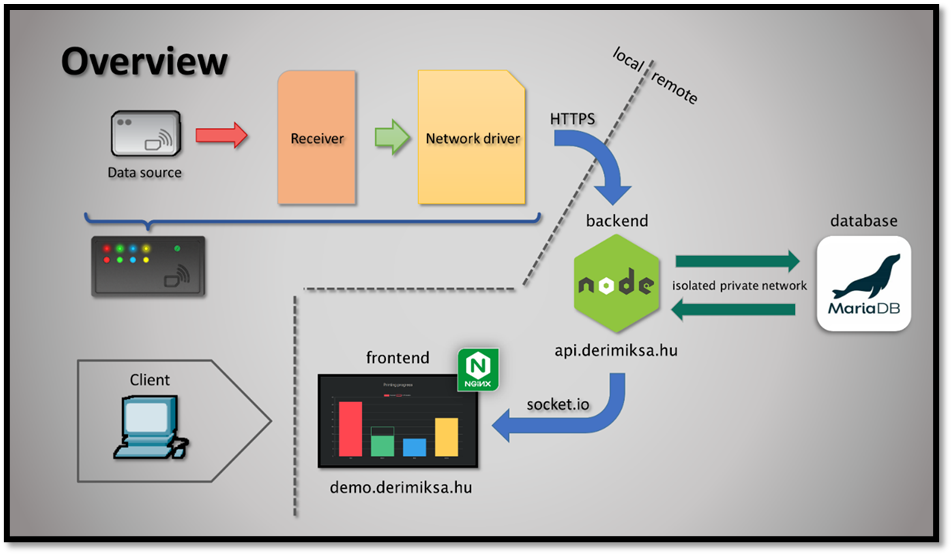

Our task in the project is to keep track of the disks in a central database by processing signals from the various workstations. Our students are also working on the webshop in cooperation with German students.

Our system is ready to receive and process data from all workstations in all participating countries

in the near future. First we are connecting the German chip sorter to the system.

Our system is ready to receive and process data from all workstations in all participating countries

in the near future. First we are connecting the German chip sorter to the system.